Examine This Report on Extrusion Of Plastics

Wiki Article

The 10-Minute Rule for Plastic Extrusion Profiles

Table of Contents9 Easy Facts About Plastic Extruded Profiles ShownThe Facts About Plastic Extrusion Companies UncoveredSee This Report on Plastic Extruded ProfilesThe smart Trick of Extrusion Of Plastics That Nobody is Talking AboutWhat Does Extruded Plastic Profiles Mean?

At Vip, we have years of experience manufacturing hundreds of special custom-made plastic extrusions in practically every form, size, and shade you can visualize - http://www.rn-tp.com/index.php/news/spring-trip?page=34#comment-133647. Our specialty hinges on making plastic accounts specifically for a specific application. You inform us what you require and we will manufacture it, fulfilling the greatest high quality criteria.From pre-prototype to post-production, ACE has the capacity as well as innovation to do it all. We serve large and tiny business in industries ranging from automotive to clinical, with tough product requirements to tight resistances in America, copyright, Mexico, and also Europe. Despite where you are or what industry you represent, you can trust ACE for customized service and client fulfillment.

That means fast quotation solution or material recommendation is just a telephone call away - https://www.avitop.com/cs/members/k3ll3rpl4st8.aspx. Your inquiries are constantly addressed quickly by our adept solution staff, as well as you get the support you require with no hold-ups or complication. Thanks for seeing our site, we are here to aid you. Please contact your ACE sales agent at 414-332-8133 or email to review services and products.

About Custom Plastic Extrusions

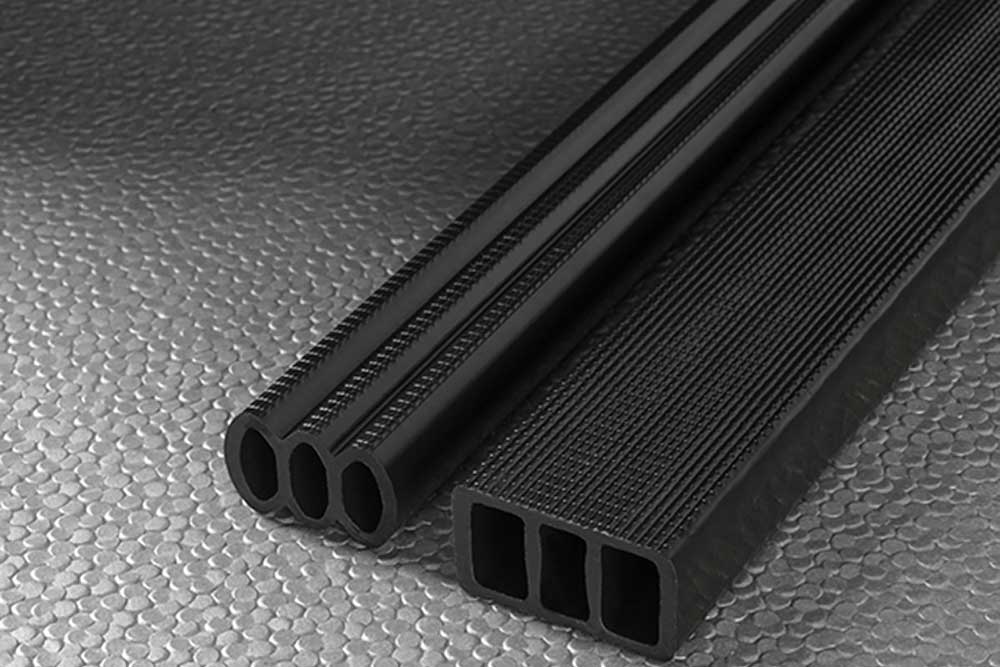

With over 100 mixed years of experience in plastic extrusion, GSH Industries is a premier B2B provider of custom plastic extrusions, tubing, and also plastic accounts in Northern Ohio. Our designers and engineers can help you in selecting the very best products for your item line - https://www.theverge.com/users/k3ll3rpl4st8. We have a huge selection of plastic resins and can match any type of customized colors to your client's requirements - custom extrusion manufacturer.It is among one of the most preferred means plastic parts are presently produced as a result of its flexibility. Customized extrusions can be developed into complex shapes of differing densities, strengths, sizes, colors, and also appearances, as well as are fairly easy to deal with. The extrusions can also be developed with efficiency improving qualities such as fire resistance, enhanced resilience, enhanced toughness, anti-friction or anti-static homes, and also a lot extra.

It can additionally potentially bring about longer cooling time with will boost your overall manufacturing time as well as expenses. Sharp corners and notches develop weak points in the account where splitting or failing can happen given that they minimize the influence resistance of the profile by creating a high anxiety concentration. Preferably, when creating your profile extrusion sharp edges ought to be prevented entirely instead go for rounded edges.

About Custom Plastic Extrusion Manufacturers

Ideally the span should be equivalent to the wall surface density of the extrusion. This adds to smoother product flow during extrusion as well as much less tension on the profile's corners. They require added alterations to the die to make sure proper product circulation, can create uneven air conditioning, as well as can create areas of weak point that can result in failure.If your part should have hollows, a hollow within an additional hollow is never ever a good idea. It will certainly be dislodged of shape prior to the extrusion strengthens - https://coub.com/johnwynn03103. If your extrusion needs attributes such as legs, grooves, snap-ins, or various other products inside of the extrusion it is best to develop a quickly obtainable opening right into the extrusion to ensure that you can better include those attributes.

The Best Strategy To Use For Plastic Extruded Profiles

Understanding some customers might be not familiar with our plastic profile extrusion abilities, we have assembled a listing of concerns we are frequently asked. Durometer is a dimension of the material's hardness and is gauged with a gadget which is pressed versus the profile's surface area, causing a dial guage analysis.

Usual ranges are Coast A for versatile materials and Coast D for rigid substances. Twin durometer, or co-extrusion, is the fusion of 2 or more products of differing physical homes into a solitary extruded item. An instance would be an inflexible component with adaptable fingers that might be utilized as a gasket or pillow.

Depending on the part intricacy and also raw materials, one can estimate the costs beginning at much less than $1,000. Due to varying set-up prices and run efficiencies, we attempt to restrict the minimum manufacturing quantity to 1,000 lineal feet.

Indicators on Plastic Extrusion Companies You Need To Know

Initially, what causes the line. If you take a close consider a drawing for a plastic profile with a crossway leg, you will certainly see there is even more mass in the area of the crossway. Given that thermoplastic products reduce some throughout the cooling process, the intersection of two legs cools down at a slower rate than the rest of the account, causing it to shrink more because of the mass of the profile.

A device developer would generally divide the circulation of both legs within the die, as well as enable them to find back together as the extrudate is being compressed to the front of the extrusion pass away. This can in some cases create a weld line where both thaw streams are revived together so mindful tuning of the extrusion webpage tooling is important to decrease this line.

Report this wiki page